Mechanical watches combine centuries-old horological craftsmanship with modern engineering. For OEMs (Original Equipment Manufacturers) considering “how to build a mechanical watch,” there are technical, logistical, and quality-driven challenges that go beyond simply sourcing parts. Every component—from the movement to finishing touches—affects precision, durability, and cost.

A well-executed mechanical watch project rewards with product prestige, higher margins, and customer loyalty. But the path demands careful decisions in design, production, testing, and after-sales support.

Essential Components & Technical Foundations

The Movement: Popular Mechanical Calibers & Performance Benchmarks

One of the first technical decisions is which movement to use: a third-party movement (e.g. Miyota, ETA, Sellita) or in-house development. Key performance metrics include:

| Movement | vph / Frequency | Power Reserve | Jewels | Common Complications | Typical Accuracy* |

|---|---|---|---|---|---|

| ETA 2824-2 | 28,800 vph (4 Hz) | ~38–40 hours | ~25 | Date, sweep second | ±4 to ±12 s/day depending on grade (“Standard”-“Chronometer”) WatchGecko+2Hodinkee+2 |

| Seiko NH35 / NH36 | 21,600 vph (3 Hz) | ~41 hours | ~24 | Day-date | ±20 to ±35 s/day typical in standard grade (lower cost tiers) |

| Miyota 9015 | 28,800 vph | ~42 hours | ~24 | Date, sweep second | Similar to mid-grade ETA, though finishing less refined |

*Accuracy ranges depend on adjustment, regulation, and build grade (number of positions adjusted, escapement quality etc.). See Hobbes vs SJX analysis. SJX Watches+2WatchGecko+2

SW200 MOVEMENT

SW200 MOVEMENT

9015 MOVEMENT

9015 MOVEMENT

NH35 MOVEMENT

NH35 MOVEMENT

In addition, take note of high-beat movements: for example, Grand Seiko’s Hi-Beat line operates at 36,000 vph, which gives a smoother seconds hand sweep and potentially better rate stability under motion or positional changes.

In-house engine vs external: Internal development gives more control over cost, finishing, supply, and branding. But R&D time, tooling cost, and consistency in performance are significant investments.

Inner-article internal link suggestion:

seiko vs citizen mechanical movement comparison

Case, Crystal, & Exterior Quality

Design and material selection for the case and crystal are critical for both aesthetics and durability.

-

Case materials: Stainless steel (316L, 904L), titanium, ceramic, even alloys or precious metals. Each has trade-offs in cost, machining difficulty, weight, durability, and finish.

-

Surface finishing: Polished, brushed, bead-blasted, PVD or DLC coatings. Poor finishing shows up as uneven lines, visible machining marks.

-

Crystal types: Sapphire crystal is preferred for scratch resistance, but adds cost; mineral glass is cheaper; some hybrid materials in between. Crystal thickness affects anti-reflective coating, profile (flat vs domed).

-

Caseback / sealing: Transparent casebacks (sapphire) add premium feel but require high precision sealing; solid casebacks easier for waterproofing. Crowns and gaskets design critical to achieve target water resistance (e.g. 30m, 100m, 200m).

Dial, Hands & Complications Integration

The dial and hands, though sometimes overlooked, are significant determinants of perceived quality.

-

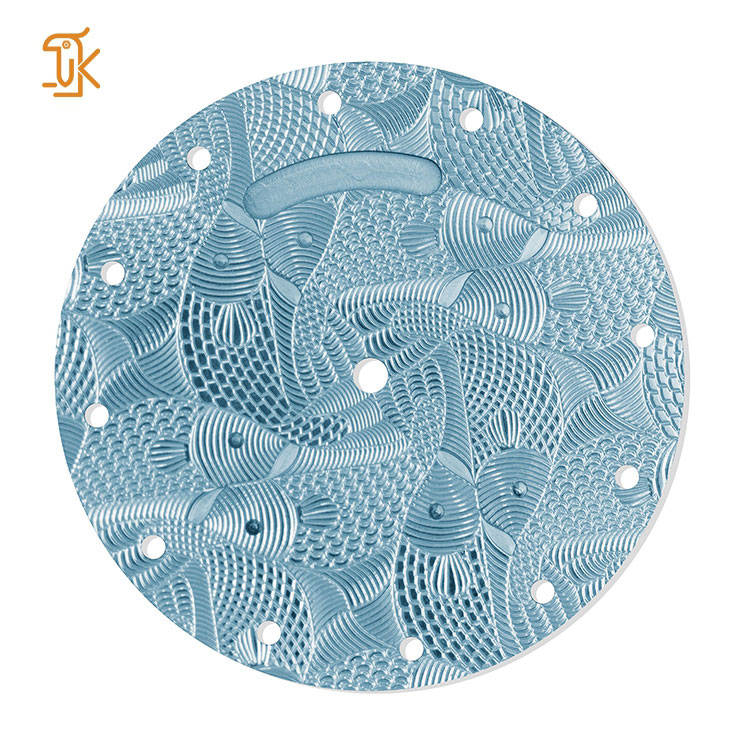

Dial design elements: Fonts, embossing or printing, applied indices vs printed, finishing (sunburst, guilloché, enamel). Subtle alignment errors (indices vs minute-track vs logo) can betray lower quality.

-

Hands: Shape, balance (center of mass), length relative to indices, filling of lume (night-glow materials), finishing.

-

Complications: Adding date quickset, day-date, moonphase, GMT etc. Each adds mechanical cams/gears, module complexity, affects movement thickness & reliability. OEM must ensure that the movement supports intended complication or source modules.

Process Workflow: Stages for Building a Mechanical Watch

Concept & Design Phase

This is where your watch begins to take form. Key considerations:

-

Define target market positioning (luxury / mid-tier / value), style (dress, dive, pilot), size, features.

-

Movement type: automatic or manual; number of complications.

-

Create sketches, CAD models, renderings. Use 3D CAD to test fit/interference between case, hands, rotor, crystal, etc.

From Romlicen’s guide, OEMs stress feasibility feedback early—design elements may need revision to suit manufacturing constraints (e.g. case wall thickness, tolerances) or cost.

Prototyping & Sample Verification

-

Prototype production via CNC, 3D printing, or hand tooling. Once prototype ready, several verification steps:

-

Fit & finish: check edges, chamfers, polish consistency.

-

Functional test: movement fits case; hands clear crystal and dial; date transitions cleanly.

-

Water resistance (if applicable), crown operation, bezel fit (for diver style), strap/bracelet fitting.

-

-

Expect iteration cycles: design → prototype → adjust → prototype until sample is acceptable. This phase often takes several weeks to a few months, depending on complexity. For example, AmericanWatch’s FAQ puts prototype stage at ~60-90 days. American Watch Company

Components Procurement & Supplier Strategy

-

Key components: movement, crystal, case, crown, hands, dial, gaskets, strap/bracelet.

-

Evaluate suppliers by: quality, consistency, certifications, delivery timelines, cost.

-

Material and component compliance with standards (e.g. if exporting to EU, RoHS / REACH; if selling in mid/high segment, consider ISO water resistance & anti-magnetism).

-

Minimum order quantity (MOQ) typically significant for components; negotiating good supplier terms is critical.

Assembly, Testing & Quality Assurance

-

Assembly under controlled environment (clean or semi-clean, avoiding dust/dirt inside movement).

-

Testing:

-

Rate / Accuracy: multi-position testing; temperature compensation if relevant.

-

Amplitude / Beat error: checking balance wheel performance.

-

Water resistance: pressure testing for diver / splash / daily wear standards.

-

Shock / Vibration: drop tests or simulated impacts.

-

Durability: strap/bracelet wear, clasp strength, crown reliability.

-

watcheshome describes QC tolerances as tight as ±10 microns in precision components for high-end OEM work. watcheshome.com

Operational & Business Considerations

Production Timeline, Lead Time & Project Management

-

Realistic timelines for full mechanical watch: Design (2-4 weeks), Prototyping (4-8 weeks, sometimes longer), Component sourcing (time depends on supplier lead time), Assembly + QC (~2-4 weeks), Packaging + Shipment. Total often 3-6 months (or more) depending on complexity. OpsWatches gives example timelines: mass production 50-55 days after sample approval, prototype shipping etc. Watcheshome watch

-

Delays often stem from design revisions, component shortage, supplier delays, QC failures.

Cost, Scaling & Pricing Strategy

-

Cost breakdown typical: Movement (~30-40%), case/crystal/caseback (~15-25%), dial & hands (~10%), strap/bracelet (~10%), finishing & QC (~10-20%), packaging, logistics, overhead.

-

Larger volume lowers per-unit cost; custom parts or finishing drive up cost substantially.

-

MOQ matters: many OEMs require orders in hundreds to thousands; small batches cost more per unit.

Certifications & Regulatory Compliance

-

ISO standards (e.g. ISO 3159 for chronometer standards), though many mechanical watches do not carry chronometer certification, can help in premium segment.

-

Material regulations: RoHS, REACH (for metals, lume, coatings).

-

Water resistance certification, anti-magnetism, sometimes specific customer markets have extra requirements (e.g. marine, diving).

After-Sales Support, Spare Part Supply & Brand Maintenance

-

Spare parts availability is essential for dial, hands, movement parts, crystals, gaskets etc. OEM should ensure supplier network can supply them long-term.

-

Maintenance service: lubrication intervals, servicing procedure, warranty.

-

Branding components: logos, engravings, packaging, certificates—all influence perceived value.

Common Pitfalls & Best Practices

-

Design vs manufacture mismatch: overly thin case walls, misaligned hands, insufficient clearance. Always verify in prototype.

-

Quality inconsistency: variation in batch finishing, colour matching, lume application, alignment can degrade brand reputation.

-

Neglecting supply chain risks: single source for critical component can lead to delays or cost spikes.

-

Underestimating testing necessary: skipping water resistance or shock tests for marketing reasons can lead to returns or failures.

-

Best practice: define and document technical spec sheet early; use mock-ups/prototypes; insist on frequent QC; partner with OEMs who have strong references.

Conclusion: Strategy for Successful Mechanical Watch Building

To summarize, “how to build a mechanical watch” as an OEM involves more than design: it’s about setting precise technical specifications, choosing reliable movements, ensuring materials & components quality, establishing rigorous QC & testing regimens, and preparing for after-sales.

Strategic steps:

-

Begin with clear concept + spec sheet

-

Use prototype phases to uncover and correct issues

-

Select components and suppliers carefully, considering cost vs quality trade-offs

-

Build QC checkpoints into every phase

-

Plan logistics, certification, and after-sales from the outset

External References & Further Reading

-

Watcheshome: The Most Popular Watch Movements Watch movement