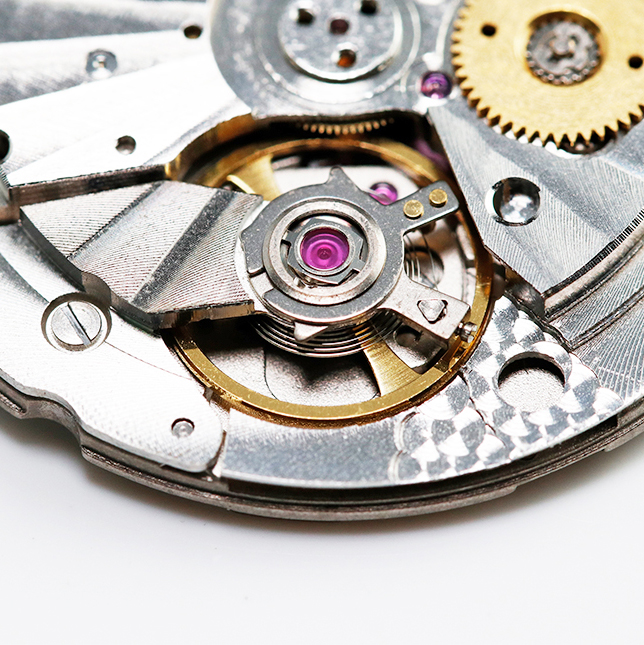

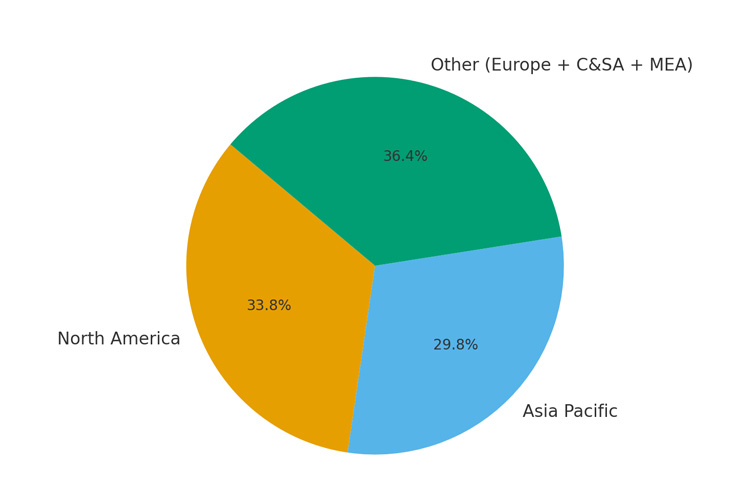

Your choice of mechanical movement is a strategic decision—it affects brand positioning, production cost, service lifecycle, and long-term product performance. Selecting the right calibre is not just a manufacturing detail but a brand imperative. There are key industry signals to be aware of: according to a market report, the global mechanical watch market was estimated at USD 61.9 billion in 2024, with forecasts reaching USD 64.8 billion in 2025, and further growth to approx. USD 97 billion by 2034 at a CAGR of ~4.6%. Global Market Insights Inc

Additionally, understanding the movement-supply ecosystem—including major manufactures, regional networks, and spare-part availability—is crucial for any brand planning its collection.

This article provides a structured decision-framework for mechanical movement selection, tailored to brands and manufacturers.

Defining Your Collection Requirements

Brand Positioning & Target Market

Your movement choice must reflect your brand’s positioning: entry-level, mid-tier, luxury. For example, a luxury brand may opt for an in-house or highly finished calibre, while a mid-tier brand might choose a reliable standard movement. Know your target buyer’s expectations: precision tolerance, heritage value, servicing infrastructure, or story value.

Functional Specification & Complication Level

The number and type of complications (date, day, chronograph, moon-phase, etc.) have direct impact on the calibre. More complications = more parts, higher cost, higher servicing demands. Ensure the movement thickness, diameter, power reserve, and beat-rate align with your design constraints and lifetime service ambitions.

Budget, Pricing & Total Cost of Ownership

Look beyond initial movement cost: include tooling, assembly, servicing, spare-parts inventory, and warranty exposure. Movement choice entered early in the product lifecycle affects cost structure and margin. Consider how MOQ (minimum order quantity) and service support will scale.

Movement Ecosystem & Supply Landscape

Be aware of the supplier ecology: major movement manufacturers and their regional spread. A guide lists key players (Swiss: ETA, Sellita; Japanese: Miyota; Chinese: Hangzhou, Yinbei) and their ramifications. Watcheshome

Assess whether your chosen movement has spare-part availability, long term support, and risk of supply disruption.

Evaluating Movement Options

Standard vs In-House vs Customized Movements

-

Standard movements (external, off-the-shelf) are cost-efficient and often supported.

-

In-house movements offer brand differentiation but impose higher cost & risk.

-

Customized movements (modifying standard calibre) provide a middle path.

Evaluate each path in terms of cost, time-to-market, serviceability, and brand value.

Reliability, Accuracy & After-Sales Support

Reliability and accuracy are core technical metrics. Brands must assess movement tolerance (e.g., ±4 s/day vs ±10 s/day), robustness, spare-parts availability, and servicing network. A deep technical guide on movements covers these attributes in detail. Teddy Baldassarre

Ensure your movement choice supports your brand’s service promise.

Compatibility with Case, Size & Design

Check movement dimensions (diameter, height), module layout, and compatibility with your case design. An oversized or overly thick movement may force non-ideal design compromises or increased case height.

Supplier & Spare Part Support

Serviceability over time is key: confirm that the movement manufacturer commits to parts supply (10-15 years or more), licensing of modules, and that your contract includes support for service, repair, and spares. A comparison table of standard vs in-house vs custom movements on support-metrics may help in decision-making.

Final Selection & Implementation Strategy

Supplier Qualification, Contract Terms & MOQ

Vet your movement supplier: audit manufacturing capacity, quality systems, reliability history. Contractual terms should cover minimum order quantity, lead-time, spare-parts availability, price escalation provisions, warranty obligations, and termination clauses.

Prototype Testing & Quality Verification

Before mass production, prototype your integrated watch (movement + case + dial + hands). Test for time deviation, shock resistance, water resistance, finishing/assembly issues. Only after thorough sample validation should full production commence.

Lifecycle Management & Brand Promise

By selecting a movement you are making a long-term commitment: servicing infrastructure, spare-parts logistics, movement phasing out strategies. Brands must plan lifelong support: indicate service intervals, parts availability, and repair costs.

Conclusion: Strategic Movement Selection for Brands

To summarise: mechanical movement selection is among the most strategic product decisions for a watch brand. It involves balancing brand positioning, functional specification, cost, serviceability and supply-chain strength. A well-chosen movement sets the foundation for long-term brand credibility and product longevity.

Brands that embed movement-decisions early into the product roadmap will be best positioned to compete, differentiate, and support their clients effectively. Watcheshome movement