In the global watch industry, OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) are two fundamental business models that define how brands collaborate with factories. Understanding these production structures is crucial for watch brands, wholesalers, and private-label companies that seek to balance design freedom, production speed, and cost efficiency.

In this guide, we will explain the differences between OEM and ODM watches, explore their advantages and limitations, and help you choose the right model for your business growth.

1. Understanding OEM and ODM in Watch Manufacturing

What is OEM in the Watch Industry?

An OEM watch project is fully developed based on the client’s own design specifications. The client provides sketches or CAD drawings, selects components such as the movement, case, and dial, and works closely with the factory for prototyping and assembly.

OEM manufacturing is ideal for established watch brands that prioritize originality and exclusivity. It offers complete control over aesthetics, materials, and branding — allowing brands to build long-term identity and market differentiation.

For example, a European boutique brand might partner with a Hong Kong factory to produce a 40mm automatic diver’s watch with a Seiko NH35 or Miyota 9015 movement, custom case, and applied indices.

✅ External Sources:

What is ODM in the Watch Industry?

In contrast, ODM (Original Design Manufacturer) watches are based on the manufacturer’s own pre-developed designs. The buyer can apply minor changes such as logo engraving, color adjustments, or strap customization.

ODM production offers speed and lower cost, making it a preferred choice for startups and fast-fashion watch brands entering the market quickly.

Example: A new online retailer chooses an existing automatic skeleton model, adds a logo on the rotor, modifies the strap color, and launches under its own brand name within 45 days.

2. Key Differences Between OEM and ODM Watch Production

| Aspect | OEM Watch | ODM Watch |

|---|---|---|

| Design Ownership | Brand/Client | Manufacturer |

| Customization Level | Full design freedom | Limited customization |

| Development Timeline | 4–6 months | 1–3 months |

| Initial Investment | Higher (tooling & R&D) | Lower (existing molds) |

| MOQ (Minimum Order Quantity) | 300–500 pcs | 100–300 pcs |

| Target Clients | Established brands | New entrants/startups |

✅ External Source:

Statista: Global Watch Manufacturing Cost Index 2025.

3. Choosing the Right Model for Your Business

When to Choose OEM

OEM is the right choice for companies aiming to build a long-term luxury or mid-range brand with a strong design identity. It allows custom complications (such as moonphase, GMT, or open-heart) and unique case structures.

Example:

A microbrand partners with a movement factory to co-develop a 6T15 skeletonized movement featuring a day-night indicator. This innovation reinforces brand uniqueness and supports higher retail pricing.

When to Choose ODM

ODM suits small brands, online sellers, and private-label retailers who prioritize faster turnaround and reduced startup costs. It provides access to ready-to-sell models with minor aesthetic personalization.

Tip:

Pair ODM watches with premium packaging, engraved buckles, or custom color palettes to elevate brand recognition.

🔗 Internal Links Suggestions:

4. Cost, MOQ, and Supply Chain Considerations

Cost Breakdown

OEM projects include mold-making, prototyping, and testing, typically requiring a starting investment of USD 8,000–15,000. ODM projects skip tooling, reducing development costs by up to 40%.

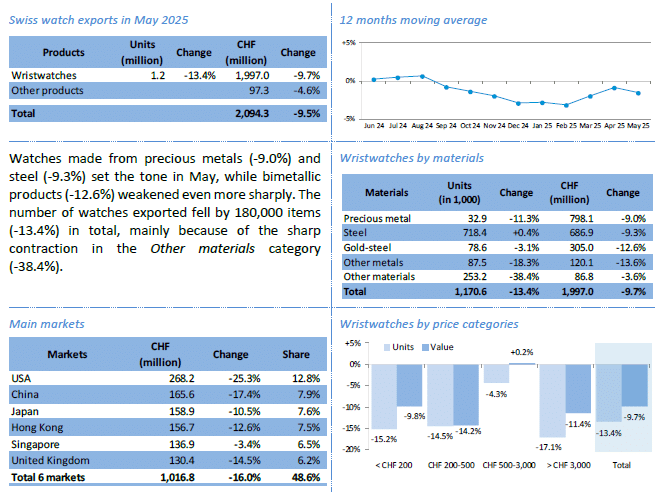

Average Unit Cost (based on 2024 data):

| Type | Average Unit Cost | Setup Cost | Lead Time |

|---|---|---|---|

| OEM Automatic Watch | $60–$120 | $10,000 | 4–6 months |

| ODM Automatic Watch | $40–$80 | $2,000–$3,000 | 1–3 months |

✅ External Sources:

Quality and Supply Chain Control

Reputable factories maintain ISO 9001, RoHS, and REACH certifications to ensure component safety and environmental compliance.

Advanced facilities use precision timing equipment such as Witschi Chronoscope to ensure accuracy and long-term performance.

5. How to Partner with a Reliable OEM/ODM Manufacturer

Key Evaluation Criteria

When selecting your production partner, assess:

-

Transparency in quotation and clear IP ownership terms.

-

In-house movement modification capabilities (e.g., Miyota, Seiko, or Sellita).

-

Experience in export logistics, warranty management, and aftersales support.

-

Availability of 3D modeling and rendering support for design validation.

✅ External Source:

WIPO – Intellectual Property in International Manufacturing.

Case Study: Hybrid Brand Growth

A European startup began with ODM quartz models, achieved quick market validation, and later transitioned to OEM for its mechanical line — balancing risk and brand development efficiently.

6. Conclusion: Align Your Manufacturing Model with Your Strategy

Both OEM and ODM models offer significant advantages depending on your brand’s goals.

-

OEM delivers uniqueness, heritage, and creative control.

-

ODM ensures speed, efficiency, and lower entry costs.

Understanding these frameworks helps you optimize your investment and production timeline while maintaining brand integrity.