Creating a truly distinctive timepiece requires more than selecting a movement and case—it lies in the art of customizing the watch hands and indexes. As two of the most visually defining elements on the dial, they significantly influence legibility, brand identity, and overall design language. For watch brands, microbrands, and OEM manufacturers, mastering custom watch parts is a powerful way to elevate craftsmanship and create a signature aesthetic that stands out in a competitive market.

Introduction — Why Hands & Indexes Matter in Watch Customization

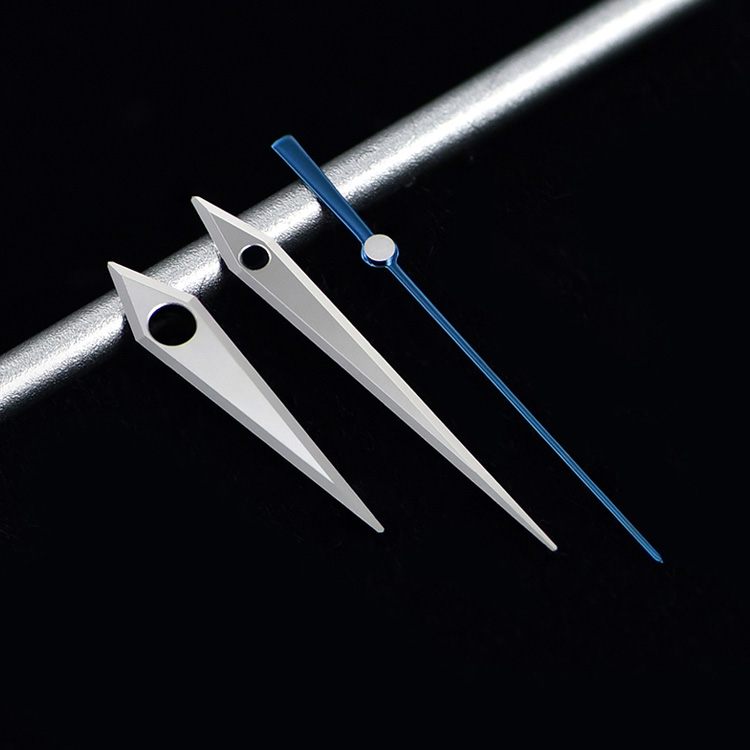

Watch hands and indexes are the components users interact with visually every second. Their proportions, finishing, materials, and positioning shape the personality of the watch—from sporty to elegant, from minimalistic to highly technical. Customizing them allows brands to build a recognizable identity, improve dial readability, and differentiate their collections with unique visual signatures.

Core Design Principles for Custom Watch Hands

1. Length, Balance, and Proportion

The length of each hand must match the dial layout precisely:

-

Hour hand reaches the hour indexes without overlapping them.

-

Minute hand should sweep close to the minute track for readability.

-

Second hand must be finely balanced to ensure smooth movement and prevent wobbling.

Incorrect proportions can create visual imbalance or interfere with the crystal.

2. Hand Styles & Their Effects

Popular custom styles include:

-

Dauphine — sharp, faceted, elegant.

-

Sword — bold, sporty, ideal for divers.

-

Skeleton hands — reduce weight, create a technical look.

-

Leaf / Feuille — classic, suitable for dress watches.

The chosen style must align with the intended brand identity and dial theme.

3. Material & Finishing Options

Customized materials and finishes improve durability and aesthetics:

-

Materials: brass, stainless steel, blued steel, lightweight alloys

-

Finishes: brushing, polishing, sandblasting, PVD coating, heat-blued finish

A premium finish increases visual depth, especially under different light angles.

4. Color, Coatings & Lume Applications

Brands can enhance legibility and night visibility using:

-

Super-LumiNova or RC Tritec for diver or field watches

-

Two-tone or gradient coatings to match dial textures

-

PVD, DLC, or IP plating for unique color effects

Precise lume filling ensures even brightness without overflow on hand edges.

Designing Custom Indexes for a Distinctive Dial

1. Index Types and Visual Impact

Common index styles include:

-

Applied indexes — premium, dimensional, often metal-filled

-

Printed indexes — ideal for minimal or retro designs

-

Cut-out or skeletonized markers — modern, technical aesthetics

-

Arabic / Roman numerals — classic or vintage identity

Each style communicates a different design intent.

2. Materials & Manufacturing Techniques

Professional custom manufacturing uses:

-

CNC-milled metal indexes for sharp faceted edges

-

Stamping for mass production

-

Laser cutting for precision micro-detailing

-

Enamel-filled markers for luxury artistic dials

Material selection includes stainless steel, brass, or plated alloys, depending on visual requirements.

3. Lume, Coating, and Detail Work

Index customization includes:

-

Lume-filled blocks for diving watches

-

Polished facets to catch light at multiple angles

-

PVD or two-tone finishes to match case components

Fine polishing ensures the indexes align perfectly with watch hands under any lighting.

4. Alignment & Dial Integration

Accurate placement is crucial:

-

Every index must align with the chapter ring.

-

Height must match hand clearance.

-

Tolerances must be precise to avoid uneven spacing.

Good alignment drastically improves the perceived quality of the watch.

How Custom Watch Parts Create a Signature Look

1. Building Brand Identity

Brands can:

-

Establish a recognizable hand shape (e.g., Mercedes hands for Rolex)

-

Use custom index geometry as a signature (e.g., AP Royal Oak markers)

-

Reinforce visual consistency across collections

Custom hands and indexes often become a brand’s design DNA.

2. Enhancing User Experience

Well-designed custom parts improve:

-

Readability

-

Light reflection

-

Day and night visibility

-

Emotional value

A unique dial instantly communicates quality and character.

3. Ensuring Technical Compatibility

Customization must also consider:

-

Stem height and hand stack

-

Movement compatibility

-

Case and crystal thickness

-

Weight distribution for second hands

Technical misfit can lead to friction, poor performance, or hand collision.

OEM & Custom Manufacturing Services

Our professional custom watch parts services include:

-

Custom hand design, manufacturing, and finishing

-

Applied index design with CNC machining

-

Dial layout engineering and lume application

-

Compatibility checks with Japanese & Swiss movements

-

Low-MOQ support for microbrand start-ups

We help brands translate design concepts into high-precision components that reflect craftsmanship and unique identity. Watcheshome

Conclusion

Customizing watch hands and indexes is one of the most effective ways to give a timepiece a signature look. Through precise engineering, material selection, thoughtful design, and premium finishing, brands can craft watches that stand out visually and technically. Whether you’re building a new collection or refining an existing one, custom watch parts offer endless possibilities for shaping a distinctive, recognizable identity.