Introduction to Mechanical Watch Waterproof Performance

Importance of Water Resistance

Water resistance safeguards intricate mechanical movements from moisture infiltration, which can cause rust on steel components, lubricant degradation, or crystal fogging. In professional contexts like saturation diving, it withstands extreme pressures—up to 122 bars in models like the Rolex Deepsea (3,900 meters rated). This protection ensures accuracy, longevity, and functionality for daily wear or adventure.

Evolution and Standards Overview

Early 20th-century watches featured basic snap-back cases with limited splash resistance. Rolex pioneered the 1926 Oyster case with screw-down crown and caseback, achieving true waterproofing. Today, ISO 22810:2010 governs static pressure testing for mechanical watches, while ISO 6425 defines stricter dive watch criteria including readability, anti-magnetism, and shock resistance.

Engineering Principles of Waterproof Construction

Case Design and Materials

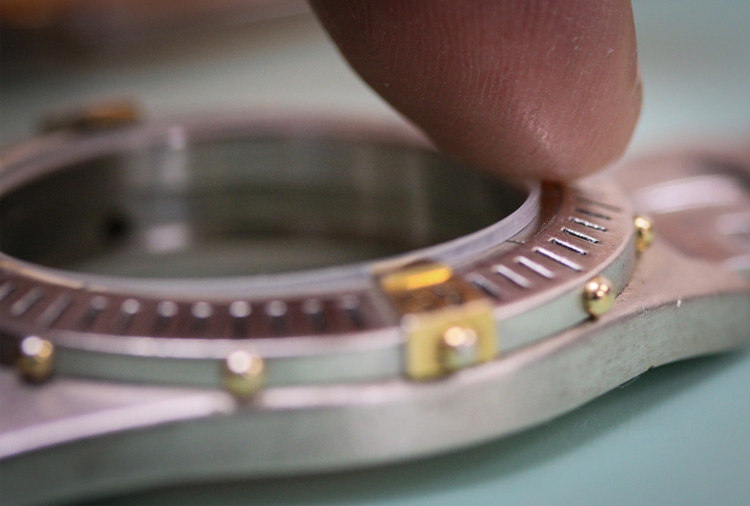

Cases use 316L stainless steel for corrosion resistance or Grade 5 titanium for lightness and hypoallergenic properties. Monobloc constructions (one-piece middle case) eliminate joints, while thick sapphire crystals (up to 5mm) and reinforced lugs distribute pressure evenly in deep-dive models.

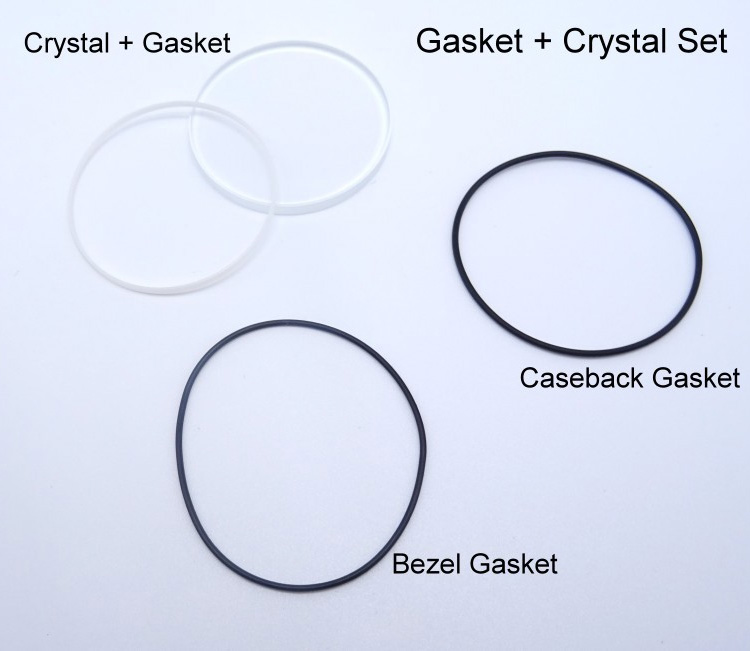

Gaskets and Seals

Primary seals employ nitrile, silicone, or Viton O-rings (0.5–1mm thick) compressed 20–30% for optimal sealing. Multiple gaskets at crown stems and caseback threads create redundant barriers, resisting aging and chemical exposure.

Screw-Down Crown and Pushers

Screw-down crowns feature threaded tubes with twin O-rings: one on the stem, one on the tube. When screwed in, they create positive compression seals rated to 300+ meters. Chronograph pushers use similar locking mechanisms to prevent ingress during submersion.

Crystal and Caseback Integration

Domed or flat sapphire crystals seat under compression with nylon or Teflon gaskets, bonded via pressure-fit or adhesive. Screw-in casebacks with 6–8 threads and wide flanges ensure even gasket compression for ratings exceeding 1000 meters.

Advanced Features for Extreme Depths

Helium escape valves (HEV) — one-way spring-loaded mechanisms at 9 o’clock — release helium atoms absorbed during saturation diving, preventing crystal expulsion during decompression. Rolex patented this in 1967 for the Sea-Dweller.

Testing Methods and Certification

ISO 22810 Standard Testing

ISO 22810 requires overpressure air tests at rated depth +25%, 2-hour immersion, and condensation checks (no internal droplets after temperature shift). Dive watches under ISO 6425 add salt water, shock, and magnetic resistance tests.

Dry and Wet Pressure Testing

Dry tests use compressed air chambers to simulate depth without water risk. Wet tests submerge watches with thermal cycling (8–40°C) to expand/contract seals, detecting leaks via bubble observation or pressure drop.

Real-World and Manufacturer In-House Tests

Brands like Omega perform “Master Chronometer” tests exceeding ISO, including 15,000 gauss magnetism and dynamic movement while submerged. Rolex uses hyperbaric tanks simulating extreme depths for Deepsea models.

Water Resistance Ratings Explained

Common ATM and Meter Designations

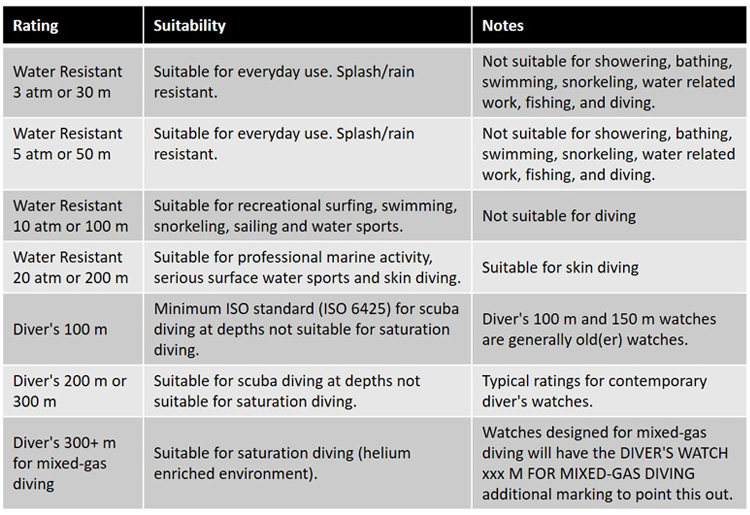

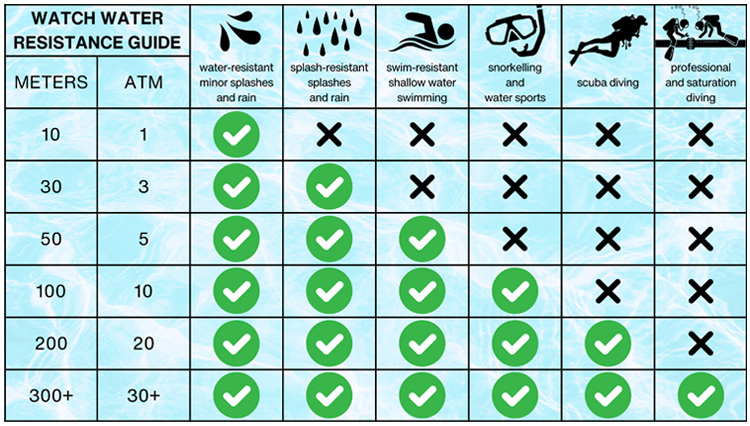

Ratings indicate static pressure: 3 ATM (30m) for splashes/hand washing; 5 ATM (50m) showering; 10 ATM (100m) swimming/snorkeling; 20 ATM+ (200m+) recreational scuba. A chart clarifies:

| Rating | Equivalent Depth | Suitable Activities |

|---|---|---|

| 3 ATM | 30 meters | Splashes, rain |

| 5 ATM | 50 meters | Showering, light swimming |

| 10 ATM | 100 meters | Swimming, snorkeling |

| 20 ATM | 200 meters | Recreational diving |

| 30+ ATM | 300+ meters | Professional/technical diving |

Limitations and Common Misconceptions

Ratings measure static pressure, not dynamic (e.g., water jets or diving impacts). Gaskets degrade from UV, chlorine, or heat, reducing effectiveness over time—no watch is permanently “waterproof.”

Maintenance and Longevity

Service Recommendations

Manufacturers recommend servicing every 3–5 years (annually for frequent divers), involving gasket replacement, lubrication, and post-assembly pressure testing to restore original ratings.

User Best Practices

Never operate crowns/pushers underwater. Rinse with fresh water after saltwater exposure. Avoid saunas or hot showers to prevent thermal expansion leaks. Store away from extreme temperatures.

Conclusion: Achieving Reliable Waterproof Performance

Balancing Design and Practicality

Mechanical watch waterproofing integrates precise engineering—corrosion-resistant materials, redundant seals, and rigorous testing—to deliver dependable protection without compromising aesthetics or movement intricacy.

Implications for Collectors and Users

Understanding these principles guides better purchasing and care decisions. High-rated mechanical watches offer versatile companions for diverse lifestyles, provided users respect limitations and maintenance schedules.