The Anatomy of a Mechanical Watch Movement — Buyer-Grade Guide for OEMs, Wholesalers & Brands

Purpose / scope: A compact, procurement-focused reference that defines what a mechanical watch movement is, breaks down BOM-level components, lists contract-grade specs and QC gates, and advises sourcing and customization for professional buyers.

Core definition & buyer overview

What is a mechanical watch movement? (contract wording)

A mechanical movement (calibre) is a mainspring-driven mechanical system that transmits stored energy through a gear train and escapement to a regulated balance, producing the rotational motion of the hands. Variants include manual-wind (no rotor) and automatic/self-winding (rotor added) movements; they are distinct from battery-powered quartz modules. Wikipedia

Buyer implication: treat the above as a PO definition and require suppliers to declare type (manual/automatic), model, and a one-line movement description in RFQs.

BOM-friendly component breakdown

Power system — mainspring & barrel

RFQ fields: mainspring material & part no., nominal torque (mN·m), barrel diameter & wall thickness (mm), rated cycle life, recommended lubrication type. Reason: torque and barrel geometry determine power reserve and minimum movement height.

Winding & rotor system — crown, rotor, reverser

RFQ fields: automatic/manual, rotor diameter & thickness, single vs bi-directional winding, rotor bearing type (bushing vs ceramic ball), rotor fixation torque. Note: rotor geometry drives case thickness and exhibition-back feasibility. (See automatic movement behaviour.)

Gear train, escapement & regulation

RFQ fields: wheel/pinion material, tooth profile tolerance (µm), escapement type (Swiss lever, pin pallet), hairspring alloy (Nivarox, Si), beat rate (vph/Hz), target average daily rate (s/day). Quantitative values here are contract test points.

Modules & finishing

RFQ fields: module interface drawing (pin/plate positions), actuation forces (N), spare-parts list, finishing level (industrial / upgraded / decorative), chamfer width (mm), plating spec (Ni/Rh/gilt). Finishing materially affects lead time and unit cost.

Contract-grade specs & QC templates

Performance thresholds (example values to include)

-

Daily rate (average): −10 to +15 s/day (standard); ±4 s/day for chronometer target (COSC). cosc.swiss

-

Power reserve: ≥ 40 h (specify residual after 24 h static test).

-

Beat rate: specify (e.g., 21,600 vph / 28,800 vph).

-

Positional variance: < 20 s/day between positions.

-

Shock/magnetic: reference ISO/COSC or supplier claim and set post-test limits.

Require batch test reports (CSV) and 5-position timing charts for pilot lots.

Manufacturing tolerances & AQL

Critical tolerances: pivot diameters ±2–5 µm; tooth profile per drawing. Recommended AQL: 1.5–2.5 for visual/functional checks; tighter for premium SKUs.

Movement sourcing & quick decision matrix

| Origin | Strengths | When to pick |

|---|---|---|

| Swiss (ETA/Sellita) | Proven parts network, high brand perception | Premium / chronometer / certified lines. SW200 |

| Japan (Miyota/Seiko) | Cost stability, volume supply | Volume automatic/mainstream lines; consistent specs (e.g., Miyota 8215). MIYOTA MOVEMENT |

| China (Sea-Gull) | Lower cost, customization | Cost-sensitive or custom modules; ensure QC controls. watcheshome |

Procurement tip: require suppliers to provide spare-parts SLA, typical lead times, and an estimated cost band in the RFQ.

Complications & customization — engineering + procurement checklist

For each complication ask supplier to deliver: functional diagram, BOM delta, added height/weight, test plan, and spare-parts schedule.

Retrograde

Mechanism: pointer travels along an arc and returns via spring/cam. RFQ checks: return time (ms), cycle life (≥100k cycles), cam material and service interval.

Jumping hour

Mechanism: instant hour jump via snail/catch or jumping disc. RFQ checks: instant-jump durability (cycles), backlash tolerance, 24-hour continuous test.

Wandering hour

Interpretation: non-linear/rotating disc displays or multi-stage indicators. RFQ: module interface drawing, sync tolerances, pilot run (10–50 units) to verify visuals.

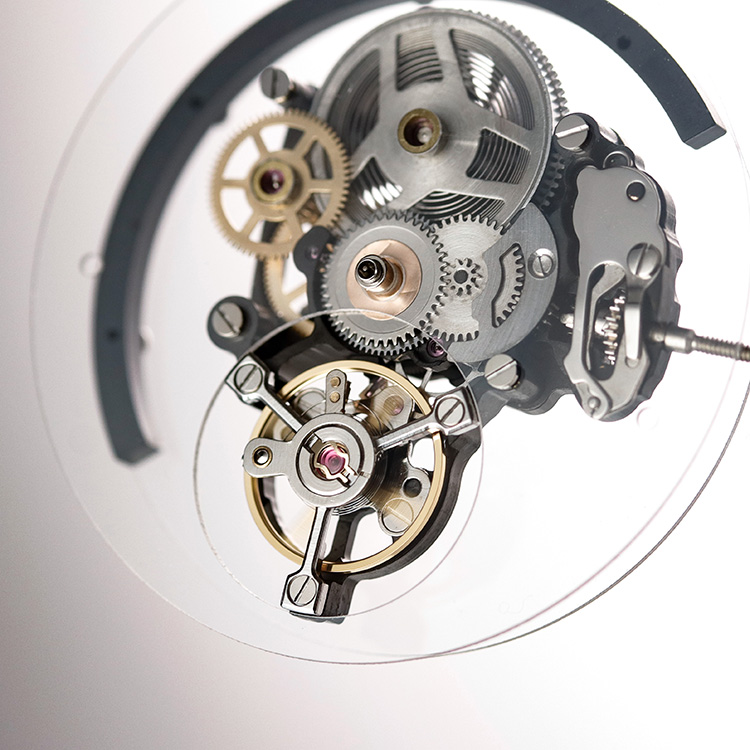

Tourbillon

High complexity and cost; requires strict tolerance, amplitude targets and defined service schedule. Use for premium image SKUs only.

24-hour striking / self-strike

Requires striking train, hammers & acoustic housing. RFQ: hammer/spring wear items listed, acoustic specs (dB), sealing & durability tests.

Sample Protocol & Supplier KPIs

Evaluation Stages

Fit & Function Verification (Gate A)

Timing & Durability Validation (Gate B)

Here, movements are tested for five-position timing accuracy, power reserve performance, shock resistance, and magnetic field stability.

Cosmetic Quality Inspection (Gate C)

At the final stage, watchmakers assess finishing consistency across all components, with close attention to brushing, polishing, and engraving quality.

Pilot Quantity & Documentation

The pilot run consists of 5–10 units. Each unit is accompanied by a complete inspection report covering functional, performance, and cosmetic results.

Visuals, downloads & internal linking (SEO + conversion)

Recommended visuals & alt text:

-

Exploded movement SVG — “exploded view of mechanical movement with mainspring, gear train, escapement, balance, rotor.”

-

Complication comparison grid (4 panels) — “retrograde / jump hour / tourbillon / striker mechanism cross-section.”

-

Procurement matrix PNG — “movement sourcing comparison (Swiss / Japan / China).”

Downloadables (host behind inquiry form): SpecSheet.xlsx (column headers prefilled), SampleAcceptance.pdf (Gate A/B/C template), QCChecklist.csv.

Conclusion & next step

Executive summary: A mechanical movement is a mainspring-driven calibre; choose Japanese/Chinese movements for volume and cost efficiency, Swiss for premium/chronometer positioning. Always include measurable acceptance thresholds, small-batch pilots, and spare-parts SLAs in contracts. MIYOTA MOVEMENTDavosa USA