A custom mechanical watch represents the intersection of artistry and engineering. For brands, crafting such a piece is more than selecting parts—it’s about transforming a vision into a tangible timepiece that reflects brand identity, technical precision, and premium value.

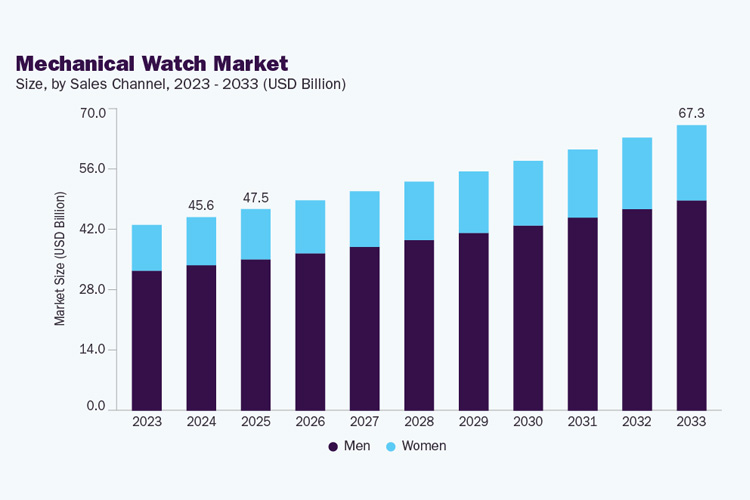

According to industry data, the global mechanical watch market was valued at approximately USD 45.57 billion in 2024, and is projected to reach USD 67.28 billion by 2033 (CAGR ≈ 4.5 %). Grand View Research+1

At the same time, successful custom watch production requires understanding manufacturing ecosystems, supply-chain partners, and movement selection strategies. This guide walks you through each stage of designing and producing a custom mechanical watch—from concept to production—ensuring your brand delivers a distinctive, well-engineered piece.

Concept & Inspiration Stage

Translating Brand Vision into Design

In the early stage, the brand must articulate its positioning, target audience, design language, and functionality goals. For example: Is this a luxury dress watch, a sports chronograph, or a minimal mechanical piece? Custom mechanical watches allow for bespoke elements: dial texture, case shape, hands style, finishing details.

By clearly defining your brand’s DNA and product ethos you set a solid foundation for technical feasibility and market differentiation.

Technical Feasibility Analysis

Once vision meets design, the next step is to assess what is feasible. Identify required complications (e.g., date, moon-phase, power reserve), case dimensions (diameter, thickness), movement type, and finishing level. Balancing creative freedom with manufacturability is key—your manufacturing partner should provide feedback on tolerances, material viability, movement compatibility, and assembly constraints.

OEM/ODM manufacturers note that many brands fail to scale because they do not align design ambitions with realistic technical specs. Watcheshome moonphase

Movement Selection and Modification

Choosing the Right Base Movement

Selecting a movement is one of the most pivotal decisions. Options include established Swiss ebauches (e.g., ETA, Sellita), Japanese movements (e.g., Miyota, Seiko), or fully in-house calibres. Each offers trade-offs: cost, availability of spare parts, brand prestige, and customization potential.

Brands targeting high-end positioning may opt for in-house calibres for exclusivity, while emerging brands may select reliable third-party movements to control cost and lead time.

In-House Modification Capabilities

Once a base movement is chosen, customization becomes the differentiator. Skeletonization (open-worked bridges), custom rotors, engraved plates, and decorative finishing upgrades elevate the watch from functional to collectible. Custom mechanical watch designs can also incorporate modules for complications, brand-specific aesthetics, and unique user experiences.

Manufacturing guides indicate OEM/ODM providers increasingly support these customization features to help brands achieve differentiation. Watcheshome

Design Engineering and Prototyping

3D Modeling and CAD Development

With movement chosen and design brief defined, CAD modelling begins. It includes modelling the case, dial, hands, rotor, and movement-case integration. The model verifies dimensions, clearances, lug geometry, crystal fit, and ergonomics—ensuring the aesthetic and functional alignment of the final piece.

Iterative reviews, visual renders, and virtual wear simulations help brands validate the look and feel before manufacturing costs escalate.

Prototype Manufacturing

The prototype phase involves machining the case (often with CNC), producing the first dial/hands samples, and assembling a working watch with the selected movement. This phase uncovers issues: fitment gaps, rotor interference, water-resistance weaknesses, hand legibility, etc.

Manufacturers recommend at least one prototype iteration and one verification sample before launch.

Image suggestion: CNC machining of watch case; prototype assembly of custom watch.

Production and Quality Control

Material Selection and Finishing

Material choices influence both cost and perceived value. Options range from 316L stainless steel, titanium, ceramic, or precious metals. Crystal materials may include sapphire with anti-reflective coating. Dial and hand finishing options may include sunburst, guilloché, brushed, or polished surfaces.

Selecting high-quality materials and finishes supports the premium positioning of a custom mechanical watch.

Rigorous Quality Testing

Quality control at production is non-negotiable. Key tests include: timekeeping accuracy, water resistance, shock resistance, visual inspection of finishes, and movement performance. For Swiss certified movements, the Contrôle Officiel Suisse des Chronomètres (COSC) criteria remain a benchmark: movements must meet seven criteria over 15 days. Swisswatches Magazine+1

Brands and manufacturers should plan for quality testing protocols, inspection logs, and tracking of deviations to ensure consistent product delivery.

Chart suggestion: Quality control checklist with pass criteria and frequency.

Branding and Customization Services

OEM & ODM Solutions

Modern watch brands often outsource to OEM or ODM partners to accelerate time to market, control costs, and access expertise. The difference lies in design control: OEM allows brand-led design, ODM provides turnkey design and manufacturing.

Working with a trusted manufacturer ensures your brand retains authenticity while ensuring manufacturability.

Collaboration Opportunities

From limited editions to region-exclusive variants, the possibility for customization expands brand storytelling. Custom mechanical watch design enables brands to offer: unique engravings, custom dial colors, bespoke straps, or even movement upgrade paths. Low minimum order quantities (MOQ) and tailored timelines are often offered by manufacturing partners to support emerging brands.

Conclusion

A custom mechanical watch is the culmination of vision, engineering, craftsmanship, and brand strategy. From concept to production, every step must be handled with precision: selecting the right movement, engineering the design, validating prototypes, and delivering quality finished products.

Given the growth trajectory of the mechanical watch market and the demand for personalized, collectible timepieces, brands that master this process will position themselves for lasting success. As the market grows, clients increasingly expect not just a time-telling device, but a story, a work of art, and an investment.