Why Building Your Own Mechanical Watch Matters

Building your own mechanical watch means more than just selecting parts—it involves defining brand identity, engineering precision, and creating value through differentiation. Whether using a fully custom movement or customizing existing ones, the process distinguishes premium manufacturers from commoditized producers.

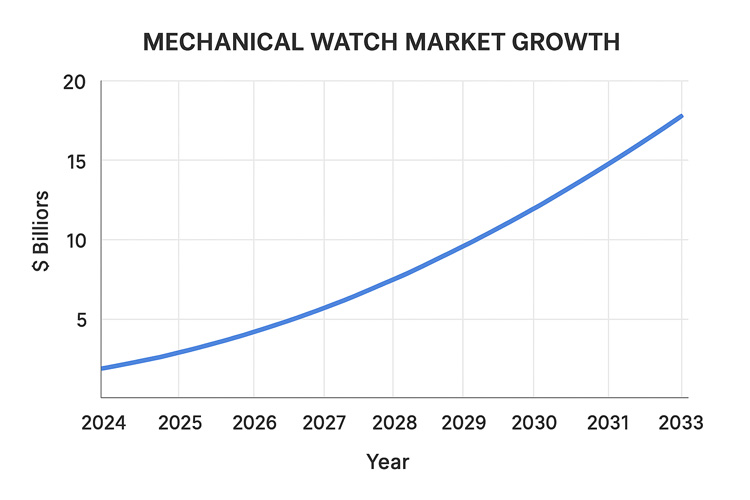

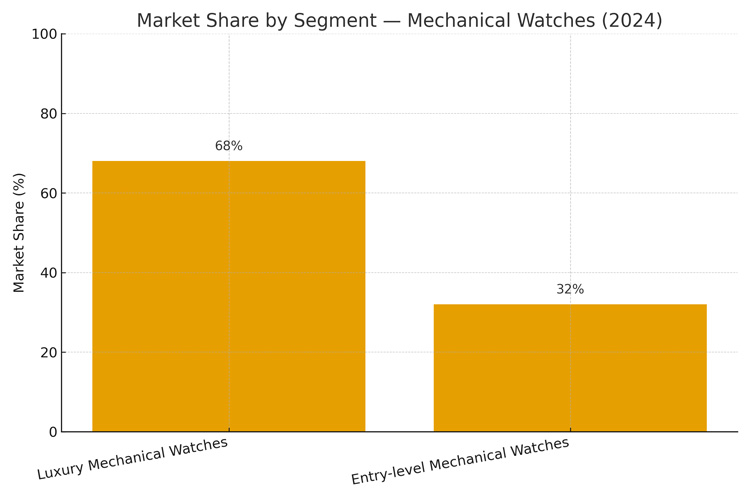

The global mechanical watch market (for luxury & mid-luxury segments) was estimated at USD 45.57 billion in 2024, with projected growth to about USD 67.28 billion by 2033 at a CAGR of ~4.5%. This reflects increasing demand for craftsmanship, exclusivity, and design authenticity. Grand View Research

In this playbook, we walk through the key phases and strategic decisions you, as a manufacturer, must master to successfully build your own mechanical watch.

Design to Prototype: Key Phases

Concept & Specification Phase

-

Define your brand vision: target audience, styling cues, price point. Materials, complications (date, chronograph, moonphase etc.), case shape, size, thickness are critical early decisions.

-

Movement choice: Swiss (Sellita, Ronda etc.), Japanese (Miyota, Seiko), or Chinese (Yinbei, Seagull, Hangzhou). Each has trade-offs in cost, accuracy, supply lead time. (E.g. watcheshome offers all three categories to meet different customer requirements.)

-

Specification sheet: tolerances, finishing, labeling/logo placement, water resistance rating etc.

CAD / 2D-3D Modeling & Ergonomics

-

Use 2D drawings + 3D CAD models to simulate case shape, dial layout, hands length, lug width, crown position. Fit and proportion in wrist wear testing (mockups) are essential for aesthetics and comfort.

-

Prototyping earlier catches mismatches between components: for example, hands might interfere with markers, crystal edge may cause glare.

Prototyping & Sample Verification

-

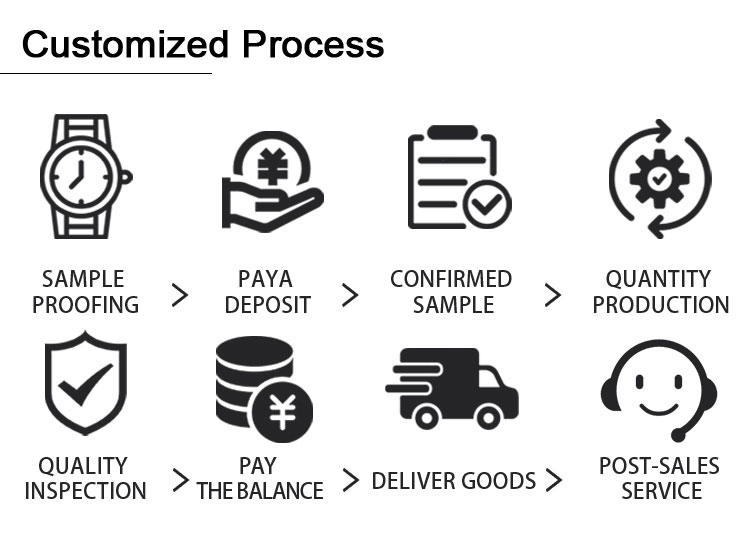

Physical prototype creation via CNC or 3D printing, to test aesthetics, tolerances, case fit, movement fit. watcheshome ODM process includes prototype review before mass production.

-

Sample verification includes water resistance tests, bezel fit (if any), crown seal, lume visibility, readability in various lighting.

-

Customer feedback → adjustments: small redesigns may include changing dial heights/button positions etc.

Manufacturing & Component Sourcing

Movement & Component Selection

-

Decide whether to use existing standard movements or develop/modify in-house or via suppliers. Each movement variant adds different numbers of parts, affecting build complexity.

-

Source reliable components: mainspring, escapement parts, balance wheel, jewels, bridges, screws. watcheshome works with Swiss, Japanese, and Chinese movements, each appropriate to different tiers of price & quality. watcheshome Movement

Materials & Finishing Options

-

Case materials: 316L stainless steel, titanium, ceramics, occasionally precious metals. Choice affects weight, machining complexity, cost.

-

Crystal types: sapphire, mineral, or specialized anti-reflective treatments.

-

Dial & hands finishing: textures (sunburst, guilloché), applied vs printed indices, polishing, brushing. Options for lume, decorative elements. watcheshome offers wide dial and hand customization.

Quality Control, Testing & Compliance

-

QC at multiple stages: incoming materials inspection, first article inspection of prototype, production line checks.

-

Testing includes time accuracy, water resistance, shock resistance, finish quality.

-

Compliance: ISO standards where required, material certifications, safety and export compliance. watcheshome emphasizes ISO-certified quality management in its OEM/ODM services. watcheshome.com

Table Suggestion: example QC checklist showing tests (accuracy, water resistance, finishes etc.) with acceptable criteria.

Production & Delivery Strategy

Minimum Order Quantities (MOQ) & Costing

-

Higher MOQs reduce per-unit tooling and setup cost, but increase upfront risk and inventory costs.

-

Custom tooling (for cases, hands etc.) adds fixed costs; budgeting must include these. watcheshome design service allows for flexible MOQs depending on project scale.

-

Timeline example: design (2–4 weeks), prototyping (2–3 weeks), pre-production verification (1–2 weeks), mass production & QC (4–8 weeks), delivery. Complexity, materials, movement type, finishing, and order size affect timing.

-

Bottlenecks often in movement shipment, finishing delays, packaging.

Packaging, Branding & After-Sales Support

-

Custom packaging and logo/branding (dial, case back, crown) help reinforce brand identity.

-

After-sales: spare parts supply (movement parts, crystals, straps), servicing network, warranties. These affect long-term brand reputation.

Best Practices & Lessons from Manufacturers

Clear Technical Briefs & Client Communication

-

Detailed specs, standard communication protocols, design reviews, sample approvals mitigate misunderstandings.

-

Using clear drawings, 3D renders, and prototype reviews ensures alignment of expectations.

Supplier Relationships & Local / Regional Sourcing

-

Reliable suppliers reduce lead time and improve quality consistency. Regional sourcing helps with logistics, import/export costs, and tighter QC oversight.

-

Example: Swiss component makers beginning to launch or revive their own brands to reduce dependence on external demand, as per FT report on Swiss suppliers launching their own high-end watch brands. financial times

Prototyping-First Mindset & Iterative Design

-

Iteration cycles reduce later production errors. Design tweaks early avoid costly rework.

-

Using prototypes to test ergonomics, readability, durability before mass production is essential.

Conclusion: Making Custom Mechanical Watches Successfully

To build your own mechanical watch successfully, you as a manufacturer must excel in:

-

Defining strong design vision and technical specifications.

-

Choosing movement & components wisely with quality & supply reliability.

-

Investing in thorough prototyping and QC processes.

-

Managing production scale, cost, and timing efficiently.

-

Delivering brand through packaging, after-sales, and storytelling.

With the mechanical watch market expected to grow (see GVR projections), opportunities for custom, well-built mechanical timepieces remain strong for those who combine craftsmanship, strategic sourcing, and intentional design.