Demagnetizing Mechanical Watches: A Factory-Recommended Method

Magnetism is one of the most common external threats to the accuracy of mechanical watches. Even the most well-crafted Swiss or Japanese movements are vulnerable when exposed to everyday electronic devices such as smartphones, speakers, and laptops. For distributors, retailers, and after-sales service teams, handling large volumes of watches increases the risk of magnetization during storage, transportation, or display.

If left untreated, magnetized watches can run minutes fast per day, resulting in warranty claims and costly after-sales issues. This guide provides a factory-recommended demagnetization method to help partners standardize procedures, protect product quality, and reduce returns.

Understanding Watch Magnetization

Causes of Magnetization

Mechanical watches often encounter magnetic fields in daily use. Strong magnets in phone cases, laptops, and speakers can magnetize the balance spring. During bulk transport, watches stored near transformers or electronic equipment in warehouses also face risks.

Symptoms of Magnetization

-

The most obvious sign is significant accuracy drift, often several minutes fast per day.

-

Second hand “jumps” or appears to stick.

-

On a timegrapher, irregular beat error or fluctuating amplitude indicates magnetism.

-

A simple compass test shows the needle reacting unnaturally when the watch is nearby.

Impact on Movements

Magnetization mainly affects the balance spring, causing coils to stick together. This reduces oscillation amplitude and severely disrupts timekeeping. For retailers.

Factory-Recommended Demagnetization Method

Required Equipment

Professional-grade demagnetizers are preferred in factory and wholesale environments. Unlike cheap consumer models, industrial machines provide stable, adjustable magnetic fields that safely neutralize residual magnetism. Supporting tools include:

-

Anti-static gloves to prevent static discharge.

-

Clean, dust-free bench to protect movement integrity.

Step-by-Step Procedure

-

Place the watch flat on the demagnetizer pad.

-

Activate the device — magnetic field pulses neutralize the movement.

-

Slowly lift the watch vertically, ensuring even exposure.

-

Test the watch on a timegrapher. If deviation exceeds +/−10 seconds per day, repeat the process.

-

Record results for traceability in B2B shipments.

Safety Considerations

-

Do not expose watches to demagnetizer longer than necessary, to avoid heat buildup.

-

Only trained technicians should handle professional demagnetizers, especially for watches with complex complications.

Alternative and On-Site Solutions

Portable Demagnetizers for Retailers

Retailers may use small handheld demagnetizers for quick fixes. While effective for basic models, they lack the precision of industrial equipment. These are best used for on-the-spot troubleshooting.

When to Escalate to Factory Service

Luxury watches with tourbillons, perpetual calendars, or multi-complications should only be serviced at factory level. Magnetization may cause irreversible deformation of the balance spring, requiring professional parts replacement.

Preventive Measures Against Magnetization

Factory Level

-

Store watches away from motors, speakers, and heavy electrical equipment.

-

Use Gauss meters to measure residual magnetism during final QC.

-

Document results in batch reports for wholesale shipments.

Distributor & Retail Level

-

Educate staff about avoiding displays near tablets or wireless charging docks.

-

Keep watches in anti-magnetic trays or pouches when possible.

End-Customer Guidance

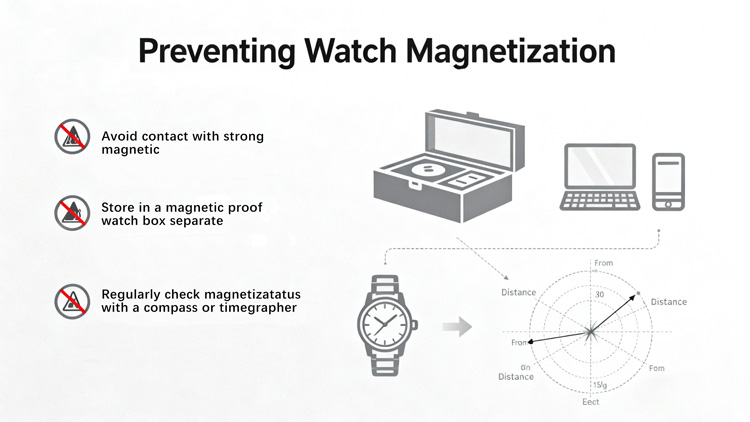

Distributors should provide care leaflets explaining:

-

Avoid direct contact with strong magnets.

-

Use anti-magnetic travel pouches.

-

Seek professional demagnetization if accuracy issues arise.

Conclusion

Demagnetization is one of the simplest yet most important after-sales procedures for mechanical watches. By following a factory-recommended method, distributors and retailers can ensure accuracy, reduce customer complaints, and protect brand reputation.

For partners, integrating demagnetization into quality control, staff training, and pre-delivery inspection ensures consistent standards across the supply chain. Preventing and addressing magnetization is not just technical maintenance—it is a safeguard for long-term commercial value.