How Accurate Are Mechanical Watches? A Buyer-Oriented Guide

For wholesale buyers, accuracy is more than a technical detail—it’s a contractual standard and a branding factor. This guide explains expected accuracy benchmarks, key influences, contract terms, QC gates, and procurement strategies.

1. Accuracy Benchmarks You Can Expect

In real-world usage, mechanical watches show varying daily deviation depending on movement grade:

-

Mass-market: ±5–15 seconds/day

-

Mid-tier automatic: ±5–10 seconds/day with factory QC

-

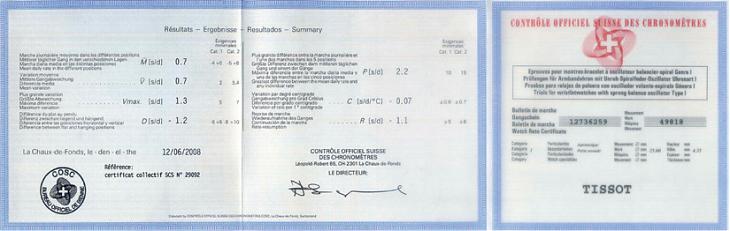

COSC-certified chronometers: -4/+6 seconds/day, tested over 15 days in 5 positions (COSC Official Standards)

-

Quartz comparison: ±0.5–1 second/day

📊 Table:

| Category | Accuracy Range | Certification |

|---|---|---|

| Basic Mechanical | ±10–20 s/day | None |

| Mid-tier Automatic | ±5–10 s/day | Factory QC |

| COSC Chronometer | -4/+6 s/day | COSC Certified |

| Quartz | ±0.5–1 s/day | N/A |

2. Why Accuracy Varies (Key Influences)

Several external and mechanical factors influence precision:

-

Temperature shifts: Metal expansion/ contraction changes balance spring tension.

-

Positional variance: Dial-up vs crown-up differences up to 15 s/day.

-

Magnetism exposure: Modern electronics easily disturb oscillation.

-

Lubrication & wear: Oil aging adds friction and error.

Innovations are closing these gaps:

-

High-frequency balances (36,000 vph, up to 10–18 Hz).

-

Hybrid systems like Seiko’s Spring Drive at ±1 s/day (Seiko Technical Reference).

📊 Chart suggestion: Error range per factor.

3. Contract-Grade Accuracy Terms (RFQ Essentials)

For OEM/wholesale, accuracy must be defined in RFQ clauses:

-

Daily Rate: ±10 s/day after 24h stabilization.

-

Temperature Range: ≤ ±5 s/day between 5–35°C.

-

Positional Deviation: ≤15 s across 5 orientations.

-

Warranty: Out-of-spec = repair or replacement. https://www.cosc.swiss/

📊 Table:

| Spec Type | Clause | Test Method |

|---|---|---|

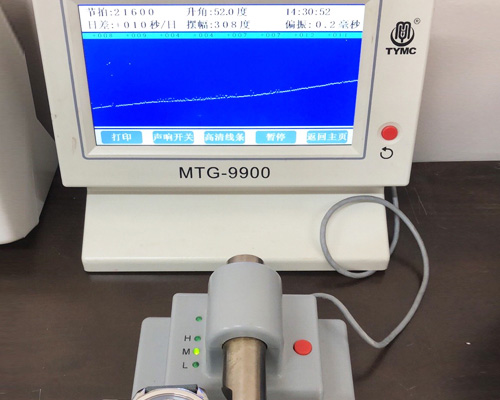

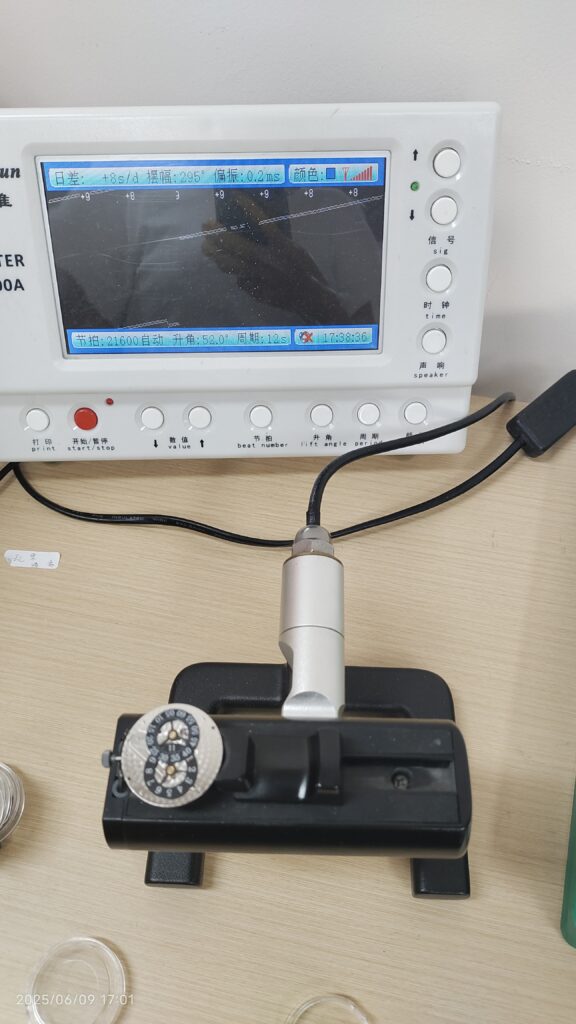

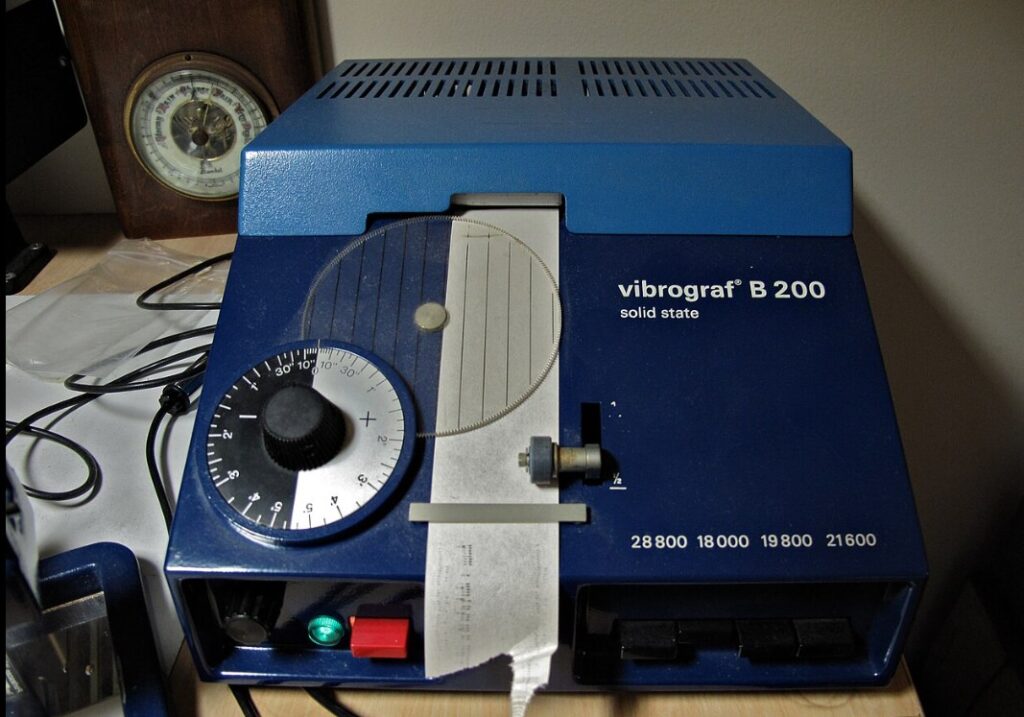

| Daily Rate | ±10 s/day | Timegrapher 24h |

| Temperature | ±5 s/day | Chamber test 5–35°C |

| Position | ≤15 s diff | 5-position test |

🔗 Internal link: https://watcheshome.com/product/jumping-hour-movement/

4. QC Process & Sample Gates

Structured QC reduces disputes and strengthens supplier accountability:

-

Gate A – Fit & Function: Winding, crown, date change.

-

Gate B – Timing Stability: Amplitude >270°, beat error <0.8ms.

-

Gate C – Cosmetic & Consistency: Dial, hands, casing alignment.

🌐 Authority source: Wikipedia – Timegrapher

5. Procurement Strategy & Technology Trends

Accuracy is both specification and brand positioning:

-

COSC vs Non-COSC: COSC adds ~$150/movement, boosting luxury perception.

-

High-beat movements: 36,000 vph signals technical prestige.

-

Hybrid innovations: Spring Drive, Atomic-sync cater to niche collectors.

📊 Matrix:

| Accuracy | Cost | MOQ | Brand Impact |

|---|---|---|---|

| ±10 s/day | Low | High | Mid-market reliable |

| ±4 s/day (COSC) | Medium | Mod. | Luxury positioning |

| ±1 s/day Hybrid | High | Low | Prestige/Innovation |

6. Final Takeaways

-

Typical accuracy: ±10s/day; COSC-certified better.

-

Procurement key: Define specs, enforce QC gates, audit suppliers.

-

Strategy: Align accuracy with segment—mid-tier (±10s/day), luxury (COSC), innovation (hybrid).