Mastering the Mechanical Watch Assembly Process

The Art of Precision Horology

Skilled watchmakers transform hundreds of tiny components—often 200 to 300 parts—into a self-powered masterpiece of accuracy and reliability. They draw on centuries of Swiss watchmaking tradition to achieve tolerances as fine as one hundredth of a millimeter through careful hand adjustments.

Our Dedication to Excellence

Our skilled artisans hand-assemble every movement in a controlled, dust-free environment that meets ISO 14644 cleanroom standards (typically ISO Class 7 or better). They follow the highest craftsmanship guidelines and perform exhaustive testing to deliver superior performance. For instance, Grand Seiko craftsmen manually refine parts for perfect fit and exceptional longevity.

https://www.grand-seiko.com/se-en/collections/movement/mechanical

Preparation for Assembly

Component Verification and Preparation

Rigorous Inspection

Watchmakers examine incoming parts under high-magnification microscopes. They check visual details, dimensions, and materials to guarantee flawless quality. In addition, they reject any defects larger than a few microns to avoid performance issues.

Ultrasonic Cleaning

Next, specialists clean components in multi-stage ultrasonic baths with specialized solutions. This step removes all residues, such as manufacturing oils and particulates. Then, they dry the parts in a filtered atmosphere to prevent recontamination.

Strategic Lubrication

Artisans then apply premium synthetic oils—like Moebius 9010 for pivots—and greases to key friction points. They use precision tools to ensure optimal longevity and smooth operation. Moreover, they select different viscosities based on part speed: lighter oils for high-frequency elements like the balance, and heavier ones for slower gear trains.

https://nobswatchmaker.com/blog/art-of-oiling-in-watchmaking

Step-by-Step Movement Assembly

Foundation Assembly

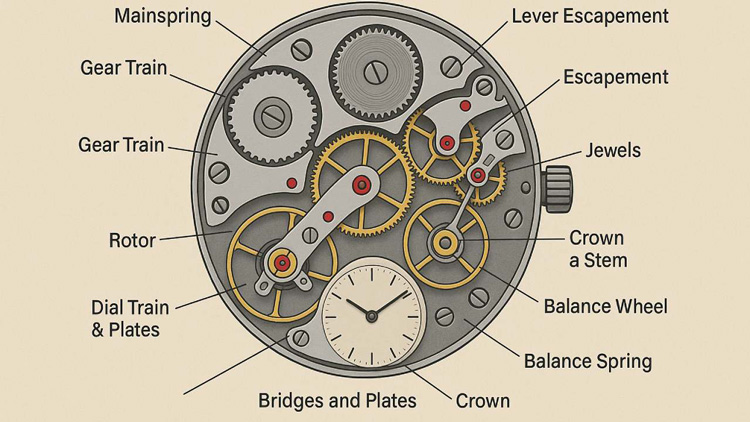

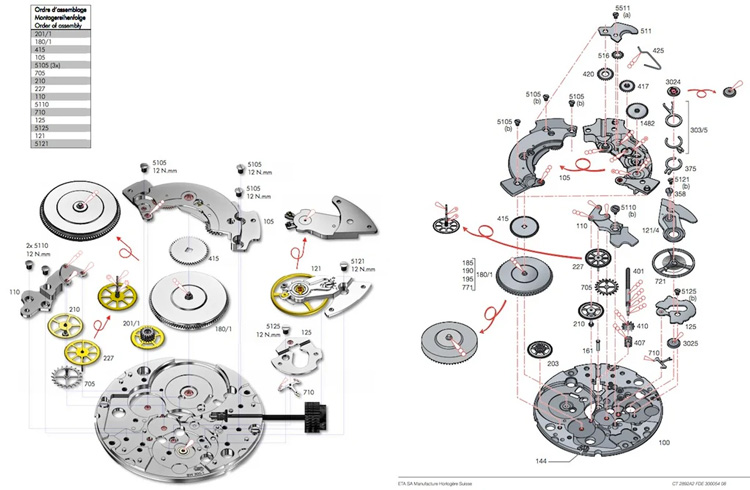

Mainplate and Keyless Works

Watchmakers start with the mainplate, the structural backbone. They install the barrel that houses the mainspring, along with the winding stem and setting mechanism. This ensures reliable crown functionality. Additionally, they grease the barrel with compounds like Moebius 8200 for even power delivery.

Gear Train Construction

After that, they precisely integrate the wheel train—including the center wheel, third wheel, fourth wheel, and escape wheel. They secure these with bridges to achieve perfect gear meshing and efficient power transmission. Finally, they verify meshing to micron tolerances to reduce energy loss.

Escapement Integration

Escape Wheel and Pallet Fork

Watchmakers delicately place the Swiss lever escapement components next. These include the escape wheel (often with 15 club-shaped teeth) and pallet fork with ruby jewels. This setup regulates energy release at micron-level precision and forms the “heart” that turns stored energy into regulated impulses.

Balance and Hairspring Assembly

The process continues with the oscillating core. Artisans mount the balance wheel, hairspring (typically Nivorox alloy for temperature stability), and Incabloc shock protection system. As a result, they ensure isochronism across amplitudes. Furthermore, they vibrate the hairspring to the exact frequency through expert poising.

https://horopedia.org/swiss-lever-escapement/)

Completion and Dial-Side Finishing

Upper Bridges and Motion Works

Artisans then secure bridges with blued screws and install the cannon pinion, hour wheel, and calendar mechanisms (if present). They often hand-finish bridges with Côtes de Genève or perlage for aesthetic excellence.

Dial and Hands Installation

Finally, they attach the dial and hands with precise alignment using specialized tools. Afterward, they perform initial manual checks for smooth operation and amplitude (usually 280-320 degrees when fully wound).

Comprehensive Testing and Regulation

Precision Timing Adjustment

Multi-Position Chronometric Testing

Experts time movements in 5-6 positions—such as dial up, dial down, and crown down—using advanced acoustic machines like Witschi or Timegrapher. They record baseline rates over 24-hour cycles.

Fine Regulation

Watchmakers then make expert adjustments to the regulator index and balance poise screws. Consequently, they achieve chronometer-grade accuracy, often within -4/+6 seconds per day or better in-house standards like Rolex’s -2/+2.

Performance and Durability Validation

Power Reserve and Amplitude Checks

They fully wind the movement and monitor run-down over 48-72 hours (depending on the caliber). This confirms specified autonomy (for example, 70+ hours in modern movements) and consistent oscillation amplitude.

Environmental Stress Testing

Next, specialists expose the movement to varying temperatures (8°C to 38°C per COSC protocol), simulated shocks (up to 5000g with Paraflex systems), and magnetic fields (up to 15,000 gauss in advanced calibers). These tests verify stability and resilience.

Final Quality Assurance

Aesthetic and Functional Inspection

Inspectors examine every detail under 10x-20x magnification. They ensure cosmetic perfection—no fingerprints or imperfect finishing—and full operational integrity, including water resistance post-casing.

Certification and Approval

The movement aligns with COSC chronometer criteria (ISO 3159: average daily rate -4/+6 seconds over 15 days in multiple positions and temperatures) or stricter in-house standards (such as Rolex Superlative Chronometer). Therefore, every piece guarantees exceptional reliability before final casing.

Through these meticulous steps, each movement becomes not just a timekeeper, but a true testament to precision craftsmanship.