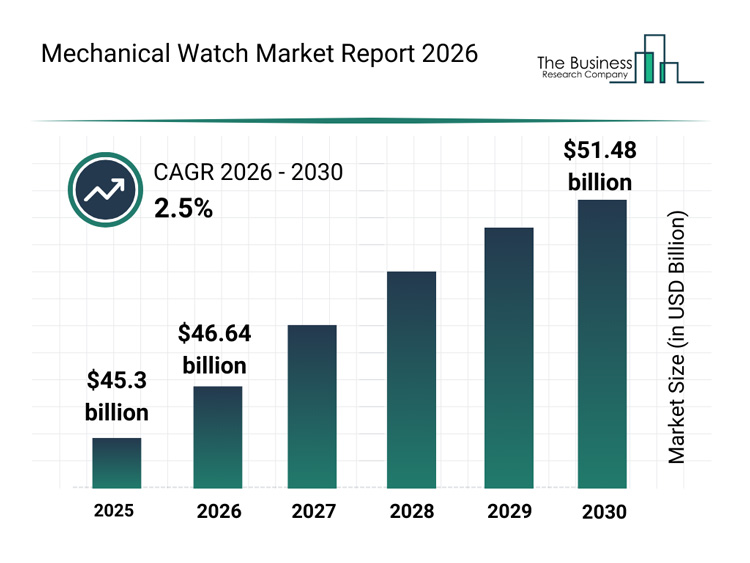

The global watch market reached USD 66.38 billion in 2024 and projects growth to USD 96.81 billion by 2033 at a CAGR of 4.3% Partnering with a professional OEM watch manufacturer like WatchesHome helps emerging brands capture this expanding market efficiently by providing manufacturing expertise, cost savings, and scalability.

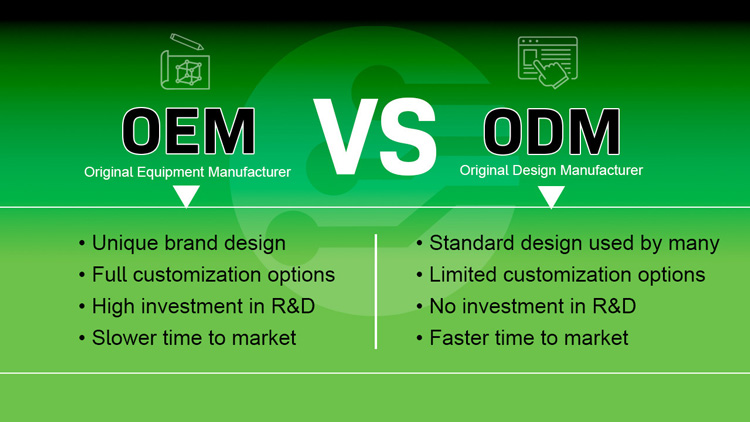

Strategic Benefits of Choosing an OEM Watch Manufacturer

Focus on Brand Development and Marketing

WatchesHome handles complete production—from design finalization to assembly. This frees your team to focus on branding, storytelling, digital marketing, and customer relationships. Brands partnering with WatchesHome often reallocate 60-70% of resources to growth activities like social media campaigns and influencer collaborations.

Lower Initial Investment and Reduced Risk

In-house factories require $5-10 million in equipment, facilities, and training. WatchesHome eliminates these costs with low MOQs starting at 300 units. Brands launch collections with minimal capital risk, testing market response before committing to larger volumes.

Scalable Production Without Infrastructure Overhead

WatchesHome’s multi-line facility supports production from 200,000 to over 300,000 units annually. Brands scale seamlessly for seasonal demands or viral hits without owning fixed infrastructure.

Expertise and Manufacturing Capabilities

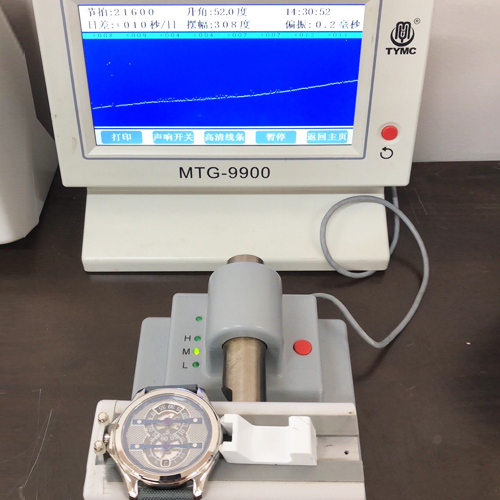

Access to Advanced Technology and Specialized Equipment

WatchesHome operates CNC machining centers, automated polishing robots, and precision pressure-testing equipment. Brands access Swiss-level tools—including laser engraving and PVD coating—without multimillion-dollar investments.

Rigorous Quality Control and Precision Engineering

Every watch undergoes 5-stage testing: component inspection, movement regulation (±10 sec/day), water resistance (up to 20 bar), and final functionality checks. Defect rates stay below 0.8%, ensuring consistent quality that builds customer loyalty.

Reliable Material Sourcing and Supply Chain Integration

WatchesHome sources certified 316L steel, sapphire crystal, and premium leathers from vetted global suppliers. This reduces lead times by 30-40% and guarantees authenticity through traceability documentation.

| Aspect | In-House Production | OEM with WatchesHome |

|---|---|---|

| Initial Capital Required | $5M–$10M+ | Under $100K for first order |

| Production Volume Flexibility | Low (fixed capacity) | High (300–50,000+ units) |

| Quality Defect Rate | 2–5% (variable) | <0.8% |

| Time-to-Market | 12–24 months | 4–8 months |

Faster Time-to-Market Advantages

Rapid Prototyping and Efficient Sampling

WatchesHome delivers 3D-printed or CNC-machined prototypes in 2-4 weeks and production samples in 4-6 weeks. Brands iterate designs quickly and launch ahead of competitors.

High Flexibility in Design and Customization

WatchesHome adapts lines for unique features like meteorite dials, custom complications, or brand-specific finishing without high minimums.

Streamlined Production and Logistics

Integrated global logistics and inventory systems ensure on-time worldwide delivery, cutting launch delays by up to 50%.

Cost-Effective Growth Opportunities

Competitive Pricing Through Economies of Scale

High-volume operations lower per-unit costs by 40-60%. Brands access premium features (e.g., sapphire crystals, automatic movements) at accessible price points.

Predictable Costs and Minimized Overheads

Transparent fixed pricing and no hidden fees simplify budgeting and forecasting.

Higher Profit Margins for Brand Expansion

30-50% production savings boost margins, funding marketing, retail expansion, or new collections.

| Cost Factor | Estimated Savings with OEM |

|---|---|

| Equipment & Facility | 80-95% reduction |

| Labor & Overhead | 50-70% lower |

| Per-Unit Production | 40-60% savings |

Long-Term Partnership Value

Consistent Quality and Compliance Support

WatchesHome maintains ISO 9001 certification and ethical sourcing standards, providing documentation for regulatory compliance across markets.

Ongoing Innovation and Technical Collaboration

Joint R&D sessions develop new features like sustainable materials or hybrid complications tailored to your brand roadmap.

Reliable Supply for Sustainable Brand Scaling

Proven production stability supports growth from startup to established volumes without interruptions.

Conclusion: Accelerate Your Watch Brand Success with a Trusted OEM Watch Manufacturer

In a competitive market growing steadily (McKinsey State of Fashion – Watches & Jewellery: partnering with WatchesHome turns manufacturing into a strategic advantage. Focus on creativity and customers while we deliver precision, efficiency, and reliability.

Contact WatchesHome today to start your OEM journey and build a stronger, faster-growing watch brand.