Correct winding is one of the most critical procedures in ensuring the longevity and performance of a mechanical watch. For distributors, retailers, and service teams handling bulk shipments, the consistency of winding practices directly impacts product reliability, customer satisfaction, and warranty claims.

Improper winding can cause damage to the movement, increase after-sales repair costs, and elevate return rates — risks that B2B partners need to mitigate through standardized protocols.

1. Types of Mechanical Watches Relevant to Winding

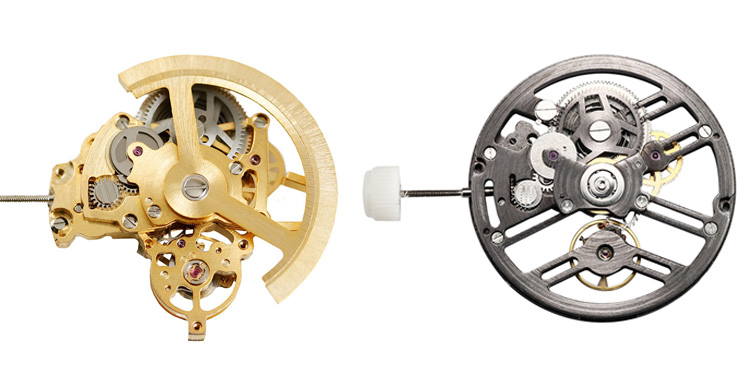

Manual-Wind Mechanical Watches

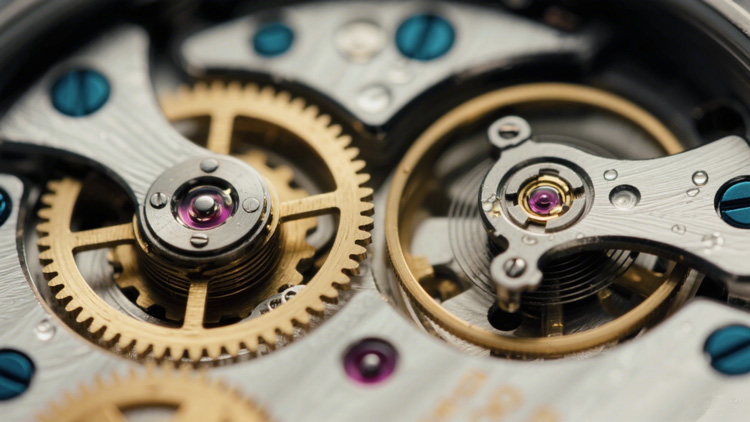

Manual-wind watches require regular winding, typically once a day or within every 40–50 hours, depending on the power reserve capacity. Energy is stored in the mainspring through direct clockwise crown rotation. This category is often used in traditional collections that emphasize classical craftsmanship.

Automatic (Self-Winding) Mechanical Watches

Automatic watches are powered by a rotor mechanism that winds the mainspring as the wearer moves. However, after long storage or during wholesale transport, these watches may stop. In such cases, manual winding is necessary before demonstration or shipment. For distributors, it is a best practice to wind automatic watches upon arrival and before placing them into retail display.

2. Preparation Before Winding

Position and Handling

Always remove the watch from the wrist before winding. This avoids unnecessary torque on the crown stem, which can lead to bending or breakage. The case should be held securely, ideally using a soft, non-slippery cloth or glove to prevent scratches.

Inspect Crown Function

Before winding, check that the crown is unscrewed on screw-down models. Ensure threads are smooth and not cross-threaded. Damaged crowns or stems are common points of failure in retail environments if staff are not properly trained.

3. Step-by-Step Winding Instructions

Manual-Wind Watches

-

Hold the watch securely with crown accessible.

-

Rotate the crown clockwise slowly and evenly.

-

Typical full winding requires 20–40 turns.

-

Stop immediately once resistance increases — continuing beyond this point may overstress the mainspring.

Automatic Watches

If stored or inactive, rotate the crown clockwise 20–30 turns to restart movement.

For bulk deliveries, provide at least 10 turns before placing into display or conducting functional testing.

This ensures sufficient power reserve for demonstrations and minimizes customer complaints.

4. Common Mistakes and How to Avoid Them

Over-Winding and Mainspring Stress

Excessive force after resistance can damage the mainspring or winding mechanism. Staff should be trained to stop winding once noticeable tension is felt.

Forcing Screw-Down Crowns

Never wind a screw-down crown without first fully unscrewing it. Retailers should ensure staff know how to properly secure and release these crowns to prevent thread damage.

Ignoring Power Reserve Cycles

Failure to wind watches before customer demonstrations or bulk shipments may lead to negative impressions or return claims. Always ensure sufficient power reserve before handover.

5. Best Practices for Distributors and Retailers

Pre-Delivery Preparation

Before shipping or handing over a watch, wind it fully and set the time correctly. For premium or limited-edition models, documenting winding cycles can add transparency and reduce disputes during warranty claims.

Training Sales & After-Sales Teams

Sales staff should be able to demonstrate how to wind a mechanical watch correctly during customer interactions. After-sales teams should guide clients with concise instructions to reduce repetitive support inquiries.

Storage & Maintenance

Display watches should be wound at least once per week. Unsold inventory should not remain unwound for extended periods, as stagnant lubricants may impair movement efficiency. Watch winders can be deployed for high-value pieces.

6. Troubleshooting Winding Issues

Crown Feels Loose or Slips

A loose or slipping crown can indicate stem or keyless works damage. In such cases, the watch should not be forced but sent to a professional service center.

Watch Not Running After Winding

If a watch remains inactive after proper winding, potential causes include escapement blockage, lubrication failure, or power train issues. Retailers should distinguish between minor issues requiring adjustment versus faults that warrant warranty claims.

Conclusion

Correct winding protocols safeguard movement integrity, enhance customer satisfaction, and significantly reduce warranty cases. For B2B partners, integrating standardized winding procedures into staff training ensures consistent quality, protects brand reputation, and minimizes after-sales costs.